- Home

- About Us

-

products

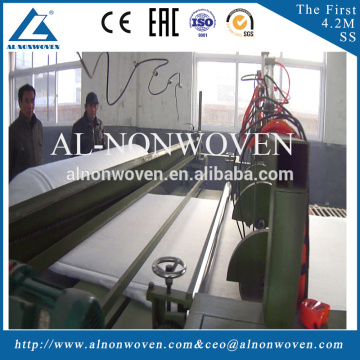

- PP Spunbond Nonwoven Machine

- PP Spunbond Nonwoven Machinery

-

PET Needle Puching/ Oven

- Bale Opener & Pre Opener& Main Opener

- Mixing Tank& Cabin blender

- Vibrating Feeder & Air Pressure Feeder

- Carding Machine

- Cross Lapper& Vertical Lapper

- Web Drafter

- Needle Punching machine

- Ironing Machine& Hot Rolling Calender

- Air Lay

- Cutter & Winder

- Stiff Wadding Drying Machine

- Spray-bonded wadding drying machine

- Other

- Pet Needle Punching

- PET Needle Punching/Oven Production Line

- PA/PES Hot Melt Web Film Production Line

- Nonwoven Bag Making Machine

- Nonwoven Fabric Printing Machine

- Film And Paper Printing Machine

- Spunlace

- Plastic Recycling Line

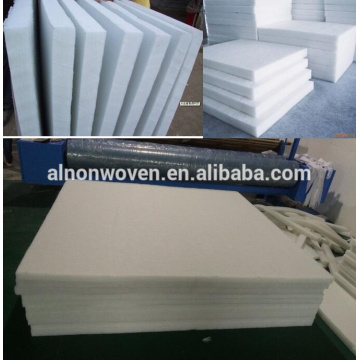

- PP Spunbond Non Woven Fabric

- PP Filler

- Mask

- Nonwoven Bag Making Machine 2

- Ungrouped

- Contact

.png) Contact Now

Contact Now