Dong Yang AoLong Nonwoven Equipment Co., Ltd. is a professional manufacturer for PP spun bonded non-woven fabric production lines ,bag making machine, PET needle punching production lines and special application treatment equipments like hydrophobic, anti-alcohol(blood, oil, static, aging, bacteria, UV) and fire retardant, which integrates project design, processing, installation and operation training of PP non-woven fabric production lines.

Our factory has many years` experienced engineers and service team to develop and install our [AL" brand of PP spun bonded non-woven fabric production lines from 1.6m, 1,8m, 2.4m, 3.2m to 4.2m with different models like S, SS, SSS,SMS and SMMS. Also production line can be customized.

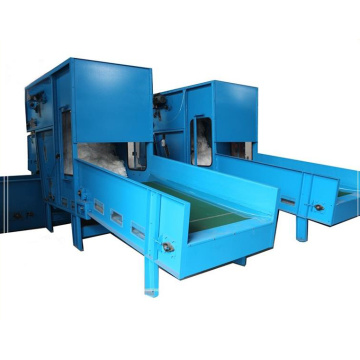

PET needle punching line includes Carpet line, PU leather line, Filtering felt line, waisted felt line, Polyfill line, Geotextile line etc.

We have our own exporting license with ISO and CE certificate, we have installed numbers of PP spun bonded non-woven fabric production lines in Chinese local market and India, Bangladesh, Turkey, Russia, Vietnam, Indonesia, U.A.E,Indonesia,Thailand,Brazil,Uzbekistan etc, Every customer`s feedback are important for our technical innovation and improvement.

We believe that only [Reasonable Quality machine with best after-sale service" can be successfully meet your special requirement

.png) Contact Now

Contact Now